Energy consumption

As part of SEA’s Energy Management System and its ISO 50001 certification, SEA Group’s energy consumption management is based on the following principles:

- energy must be produced while respecting and protecting the environment;

- reducing environmental impact and improving environmental performance are among the criteria of our business strategies, including infrastructural development;

- awareness of employees, partners, suppliers, contractors and stakeholders regarding environmental impact of their activities is a central concern for improving environmental performance at both airports.

The System provides for the settlement of an Energy Team and, for the integrated management of the more technical aspects, a Technical Group (which also includes representatives of SEA Energia). The involvement of all functions directly related to different aspects (design, implementation, maintenance and environmental management structure) ensures the necessary overview of processes and thus the identification of the most appropriate intervention proposals.

In 2015, SEA continued to implement measures in the fields of lighting, air conditioning and innovation. The measures involved:

- lighting technological improvements such as upgrades to low power and LED lamps, both indoor and for outdoor apron and road lighting;

- management improvements, such as switching off lights at night in unused places, modification of the automatic switch-off system of night lights at aprons, night switching off of the runway not being used due to noise-reduction measures or to maintenance activities;

- completing the computerisation of energy consumption data and introducing additional field meters in order to subdivide and analyse consumption more accurately;

- optimizing air conditioning plants through the reduction of the “minimum external air flow” depending on the presence of passengers, addition of inverters on heat sub-stations, optimisation of set-points for the microclimate;

- eliminating (almost completely) the decentralised production plants (boilers, refrigerating units).

At both airports, we operate cogeneration/trigeneration plants that constantly generate energy savings that benefit SEA Group, the quality of the environment and citizens of neighbouring areas. We offer high-efficiency performance generating savings for both company and customers who, thanks to the use of district heating, reap savings related to heat recovery.

Energy consumption of the SEA Group

| Unit of measure | Malpensa | Linate |

|---|---|---|

| Petrol (GJ) | 4,927 | 1,603 |

| Heating oil (GJ) | 2,548 | 73 |

| Methane (GJ) | 2,068,399 | 1,032,663 |

| Diesel fuel (GJ) | 22,434 | 9,554 |

| Purchased electricity (GJ) | 1,027 | 796 |

| Sold refrigeration energy (GJ) | 17,507 | - |

| Sold heat energy (GJ) | 19,722 | 238,489 |

| Sold electricity (GJ) | 231,144 | 237,448 |

| Total (GJ) | 1,830,963 | 568,753 |

Source: SEA

Energy intensity (GJ/unit of traffic) 2015

| Malpensa | Linate | Total | |

|---|---|---|---|

| 2015 | 0.08 | 0.06 | 0.07 |

Note: The units of traffic is equivalent to one passenger or 100 kg of freight.

Source: SEA

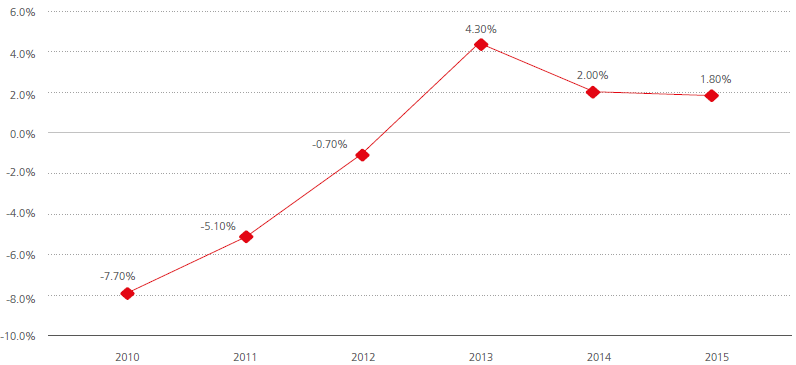

Interventions carried out at both airports led to an energy saving of 13,589 MWh in 2010 (-7.7% compared to 2009), 8,353 MWh in 2011 (-5.1% compared to 2010) and 1,080 MWh in 2012 (-0.7% compared to 2011), while in 2013 the increase of 6,665 MWh (+4.3% compared to 2012) was due to the opening of the third satellite within the airport over an area of approximately 49,600 m2. In 2014, the increase of 3,169 MWh (+2.0% compared to 2013) was lower than in 2013 despite the completion of new infrastructure spaces over approximately 18,500 m2 for operating the third satellite. Furthermore, 2015 showed an increase of 2,975 MWh (+1.8%), which was lower than 2014 considering that infrastructure spaces

were increased by an additional 4,950 m2.

Trend of the energy consumption (%)

Source: SEA